Problems of the photocatalytic method

The problem of by-products when using photocatalysis for air purification from volatile organic compounds (VOCs) is still relevant. Minimizing these is a desirable goal for all developers.

The effectiveness of using photocatalysis in air purification devices is mainly determined by the ability of the photocatalyst itself to adsorb VOC molecules in itself and the quantum yield of the photocatalyst (its ability to emit photoelectrons according to the number of incident photons) and the number of photons (Power) of the radiation source of the required spectrum. The influence of secondary factors, such as humidity, temperature, photocatalyst illumination uniformity, etc., can be considered external and less significant factors in terms of your control.

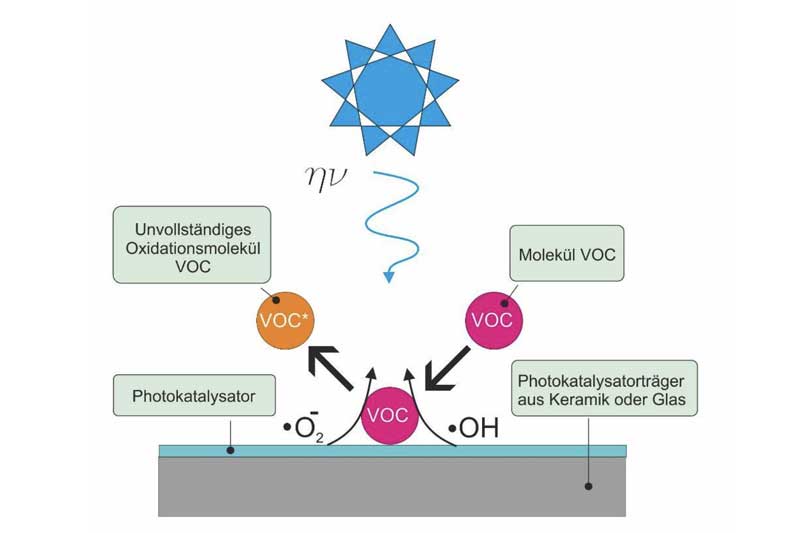

Most work on the study of photocatalysis focuses on the research of photocatalysts as such, the effect of dopants on their efficiency, radiation spectrum, etc.. Here, photocatalytic cells with deposited photocatalyst in the form of thin layers on an inorganic support are usually studied (Fig. 1 ), i.e. Schemes are considered that are obviously ineffective from the point of view of practical application, since the adsorption of VOCs by thin catalyst layers is the least effective.

Scheme: photocatalytic reactions on thin photocatalyst layers

Cells absorb air pollutants poorly. The momentary contact of VOC molecules with the photocatalyst causes intermediate products of VOC oxidation, of which formaldehyde and acetaldehyde are the most worrying, to “bounce” off the surface with relative ease. Even the porous structure of ceramic supports used by some researchers does not change anything fundamentally, because although it increases the illuminated surface, it does not change the actual scheme of photocatalytic reactions.

Even the commercial photocatalyst in the form of a Degussa P25 powder (Fig. 2), which is often mentioned in studies, cannot be regarded as optimal for VOC adsorption, since the morphology of the powder particles – in the form of individual spherical particles – does not mean the presence of mesopores in effectively capturing the VOC molecules.

Fig. 2 Degussa P25 photocatalyst

Das Arbeitsschema der Photokatalyse in Arpack-Geräten

Das Arbeitsschema photokatalytischer Zellen in Arpack-Geräten ist grundlegend anders (Abb. 3).

Fig. 3 Scheme of photocatalytic reactions in the cells of Arpack devices

Photocatalyst – titanium dioxide of the anatase modification with a very high (350 m2 / g) specific surface area and morphology in the form of porous agglomerates (Fig. 4), is fixed evenly throughout the volume of a porous glass support made of sintered glass beads. The density of its application is 1 g / dm2. In combination, this ensures very good adhesion of VOCs when air is pumped through the cell and creates conditions for the most complete course of photocatalytic mineralization reactions.

Fig. 4 Photocatalyst in Arpack instrument cells

The carrier material – quartz glass – is transparent to the radiation of the photocatalytic spectrum. As a result, the adsorbed VOC molecules are photocatalytically mineralized in the entire volume of the carrier as efficiently as possible.

The same thing happens with the pathogenic microflora of the air. It gets stuck in the volume of the photocatalyst, since the pore sizes in it are comparable in size to the microflora itself, and under the action of UVA radiation it is mineralized mainly into water vapor and carbon dioxide.

The ability of the photocatalytic cells of Arpack devices to filter microflora makes them suitable for air disinfection in cases where photocatalytic molecular purification of the air becomes impossible due to the presence of fluoro-chlorine-containing organic compounds in it (e.g. sevoflurane in operating rooms). In these cases, the process of air disinfection of the photocatalytic cells of Arpack devices can be two-stage: the first stage is the accumulation of microflora in the volume of the photocatalyst without irradiation, the second is the mineralization of microflora without their further accumulation.

This unique capability has been validated by the Fresenius Institute (Report No.: BS_20210426_RW) and enables air disinfection with Arpack devices with guaranteed absence of airborne VOC oxidation intermediates.

Results of operating Arpack equipment

Removal of formaldehyde

Formaldehyde is not removed by adsorption air purifiers. In the premises it is distinguished primarily by furniture made of chipboard.

Fig. 5 Changes in formaldehyde concentration in a box with a volume of 10 m3 as a result of operating the Arpack product with a 60 W photocatalytic cell

The initial amount of formaldehyde is 1 ml removal of acetaldehyde

Average Daily MPC – 0.34mg/ m3

The rate of acetaldehyde mineralization by the Arpack instrument was estimated using the rate of carbon dioxide (CO2) accumulation in the test box, with subsequent recalculation of the relative concentrations.

Fig. 6 Change in the relative concentration of acetaldehyde in a box with a volume of 10 m3 as a result of operating the Arpack product with a 60 W photocatalytic cell

The initial amount of acetaldehyde is 5 ml

Removal of microflora in the classroom

The capabilities of the Arpack device for air disinfection are demonstrated using the example of a classroom at the Lew Tolstoy School in Berlin. The device was turned on for 15 minutes during the break in class. Microbiological samples were taken from the impactor before turning the device on and immediately after turning it off. Air sampling points were selected using a uniform grid of 8 points. Air samples were taken at a height of 120 cm.

The results of measurements of CFU concentration (1/m3) at sampling points (Fig. 7) were brought by the method of contour mapping in the XYZ projection with the construction of a spatial interpolation grid by the Shepard method in the graphically processed software package Origin 9.0 .

Fig. 6 Change in the CFU concentration in the room air due to the operation of the Arpack device

Conclusions

Photocatalytic cells – used in Arpack devices allow photocatalysis to be maximized for molecular purification and disinfection of the air.

It is impossible to say that the cell is absolutely perfect. Theoretically, under certain conditions, e.g. at very high VOC concentrations or at very high airflow rates through the cells, the formation of photocatalytic intermediates is possible. However, if we take into account the fact that the operation of the devices is recommended with restrictions on the concentration of VOCs in rooms (at the level of several MPCs), and the devices themselves (even with a photocatalytic cell) have high efficiency in removing such “complex” pollutants , such as formaldehyde (0.2 ml/h) and acetaldehyde (1 ml/h), Arpack devices and the cells themselves can be safely recommended for molecular air purification in households of various types and purposes.

Air disinfection with Arpack devices is possible without restrictions, since the use of photocatalysis with, among other things, can be used exclusively to sterilize cells that accumulate microflora.